Issue 06: Critical Panic

Socio-environmental costs across the AI lifecycle – Part 2

In Part 2, we look at the material aspects of mineral extraction, manufacturing, and waste generation as part of the AI lifecycle. Read Part 1 here.

Dear Reader,

In a 2024 report on critical energy transition minerals, the UN Secretary-General António Guterres said, "A world powered by renewables is a world hungry for critical minerals. For developing countries, critical minerals are a critical opportunity – to create jobs, diversify economies, and dramatically boost revenues. But only if they are managed properly”.

Renewable energy components like photovoltaic solar panels, wind turbines, and lithium battery storage, while key to decarbonising the energy sector, have their own resource-intensive lifecycles that begin with mineral extraction and end with waste. Projections show that by 2040, the extraction of critical minerals and rare earth elements (REE) will have to quadruple to meet climate goals. Developments around the US-Ukraine minerals deal indicate that the future of war and peace may hinge on the ability of nations to shore up their mineral reserves.

From the frenzied demand for lithium for EV batteries, the metal mining panic has turned to the minerals required for AI’s energy demands. In 2024, commodity trader Trafigura estimated that data centres to power AI will likely require an additional 1 million metric tons of copper by 2030. Amidst tech players like Google pledging to be 100% powered by clean energy, the rush for critical minerals is on.

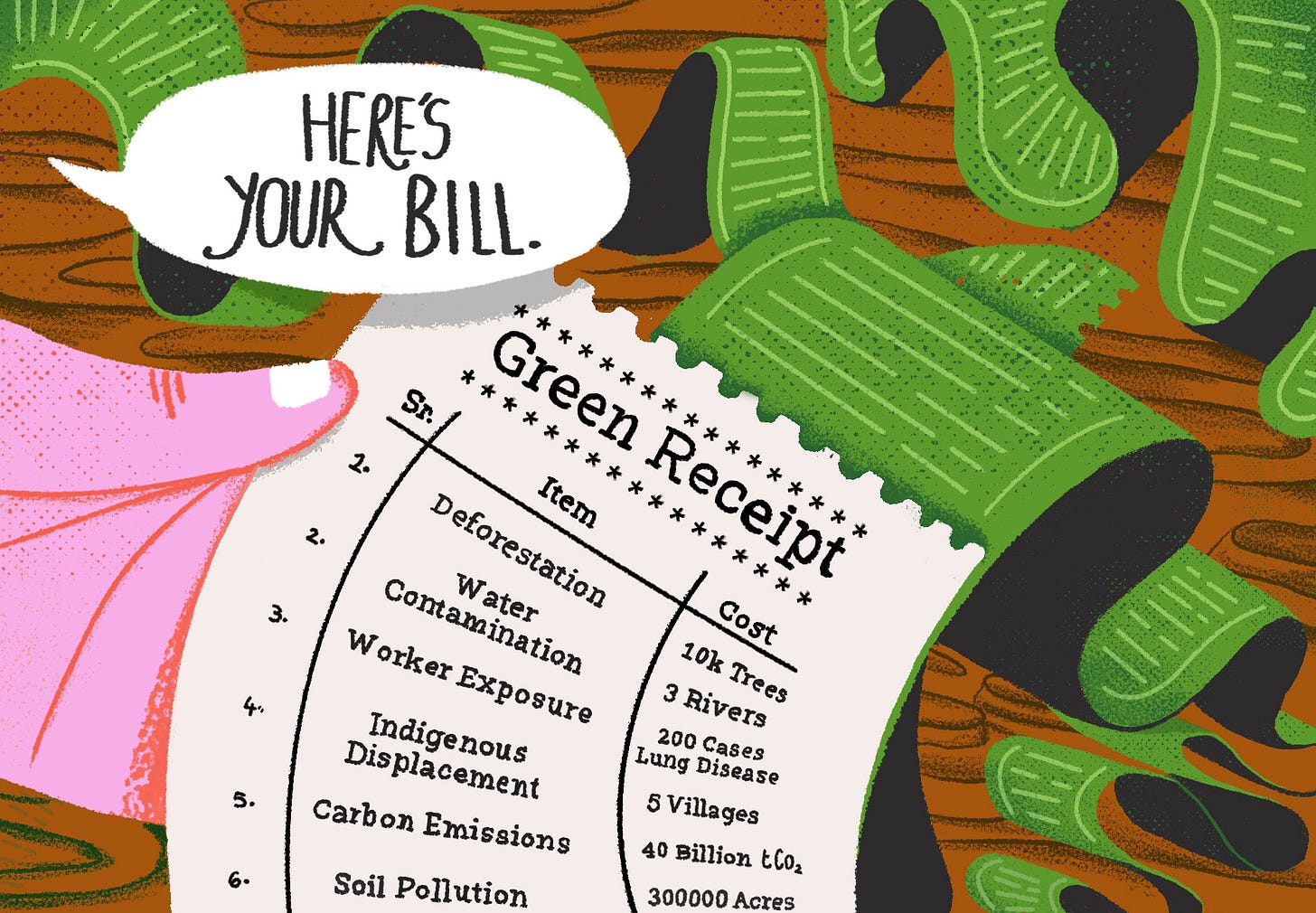

But who bears the costs of these transitions? The drive for minerals reveals unequal geopolitical dynamics as Global South countries become resource frontiers for extraction and refining. Mining has its own environmental, social and health risks, such as water pollution, industrial waste, worker exposure to toxic chemical processes, and biodiversity loss, impacting indigenous lands and communities. To meet mineral demand, initiatives for climate-smart mining have emerged - but critics warn that this is simply greenwashing masking continued harms of extractivism.

Given broader narratives around the geopolitics of mineral supply chains as well as the long-term environmental and local impacts of extraction and processing, policymakers and investors must consider the connection between AI’s growth and its reliance on critical minerals, instead of leaving it to market forces.

Curated Reads

We trace geopolitical challenges and the environmental and social implications of the mineral supply chain, AI for responsible and sustainable mining, and highlight potential pathways for environmental justice.

Paradoxical paths

The dual nature of AI and critical minerals - its potential to improve mining efficiency alongside its reliance on accelerated mineral extraction - presents a paradox. Net-zero means AI development depends on the clean energy transition, which is further driving the rush for critical minerals. This leaves ecological and social destruction in its wake, standing in tension with its potential role in optimising mineral extraction and processing.

In our research, we found that much of the literature urges increased investment in AI mining technologies and research, with efficiency as the bottom line. For example, to address funding barriers to meet mineral demands for the green transition, researchers in Australia found that the use of AI can help shorten the duration of mining projects, map mineral reserves, and reduce associated disaster and environmental hazards. However, they also note that AI’s potential in the mining sector is deeply linked with upskilling workers to use AI, filling acute gaps in databases to train and test AI models, and challenges in storing and transmitting data from remote and often inaccessible mining locations.

“Not in my backyard” politics

In the mineral production supply chain, the outsourcing of harmful social and environmental effects is characterised as an offloading of risk, a type of ‘not-in-my-backyard’ politics of industrialised economies. While nations (historically the Global North) fuel escalating demand, they shift production to countries (often in the Global South) with lower environmental standards, and labour and energy regulations, and hence, cheaper costs. In efforts to capture economic gains, these countries often do not have the luxury of prioritising social or environmental concerns.

Take, for example, the semiconductor industry which is driving demand for rare earth elements like gallium and germanium. When China, which accounts for 98% of the refined gallium and 68% of germanium production globally, imposed export restrictions in 2023, there were global impacts on supply chains, escalating already fever-pitch tensions between the US and China.

When supply chains are threatened, countries search elsewhere, typically where costs are low. Disparities within the Asian region also enable inequitable distribution of benefits and risks, as countries move damaging mining and processing intra-regionally to meet low-carbon economy goals.

China has led Rare Earth Element (REE) production since the 1980s, influenced in part by stronger environmental regulations in developed economies. REE processing involves highly toxic chemicals like ammonium sulfate and chloride to separate minerals. Now, as China’s domestic environmental standards are improving with clean-up projects underway, its activities have moved to less regulated zones like Myanmar’s Kachin State, where water contamination has impacted food security and presented health risks for workers and local communities.

Similarly, China now invests in bauxite smelting facilities in Indonesia which run on coal, making them energy-intensive and environmentally dirty, but less expensive.

Long-term environmental impacts

Salvador Regilme writes about ‘necro exportation’- how the Global North, which reaps AI’s benefits, transfers the environmental costs to the Global South, leading to ecosystem and community damage through resource extraction and energy consumption.

Historically, extraction and refining processes have endangered biodiversity hotspots, creating health risks and polluting water sources. For example, nickel mining is endangering the biodiversity-rich Sibuyan Islands in the Philippines. In Indonesia, producer of 1/4th of the world’s nickel supply, extraction and the construction of industrial parks for smelting have resulted in flooding, deforestation, and the loss of indigenous livelihoods.

The supercycles of mineral supply booms and busts also leave mining communities vulnerable to ‘legacy issues’ of mining: abandoned and derelict infrastructures, open pits and residual industrial waste, which haunt communities with soil, water, and air contamination. One of the UN Secretary General’s Actionable Recommendations includes a proposal for a Global Mining Legacy Fund to clean up these mines and to strengthen financial assurance mechanisms for mine closure and rehabilitation.

Locating place and identity

Research by the International Renewable Energy Agency (IRENA) indicates that 54% of energy transition minerals are situated on or adjacent to Indigenous territories, highlighting critical intersections between resource extraction and Indigenous rights.

In their comprehensive mapping of over 5,000 mineral projects critical to energy transitions, researchers in Australia and Indonesia found that strategic minerals like lithium and manganese have the highest spatial correlation with Indigenous territories. To ensure that the push for renewable energy does not lead to displacement and disruption for communities, they suggest improved sustainability assessments, stronger free, prior and informed consent processes, and the promotion of circular economy solutions to reduce reliance on newly mined critical minerals.

Mining also poses sociocultural risks to Indigenous cultural heritage through environmental degradation and social disruption of land-connected rites and traditions. In Papua New Guinea, proposed deep-sea mining threatens communities' access to traditional marine spaces integral to their spiritual practices and cultural identity. These authors advocate for expanding the meaning of ‘mining impacts’ to incorporate cultural heritage and recommend collaborative research partnerships with traditional knowledge holders, and localised impact studies in Global South contexts.

Health and labour

Artisanal and small-scale mines (ASM) are known for human rights abuses, with unsafe working conditions, lack of protective gear, and exploitation, including child labour. In Indonesia, more than 2000 ASM gold mines are spread across 30 provinces, many of them unlicensed and unregulated. While the Democratic Republic of the Congo is the world’s largest producer of cobalt, an important component of AI hardware, the Philippines and Indonesia also have significant reserves.

In a review, authors found that ASM is often more labour-intensive in Asia and Africa compared to other regions like South America. While the expansion of ASM for critical minerals could correlate with increased employment and income in these regions, without suitable working conditions and continued health and safety risks, ASM will exacerbate existing social problems. To combat this, the authors advocate that the sector be formalised with adequate regulatory oversight and policy enforcement.

Towards sustainable and responsible mining

Given the many environmental and social costs across the critical mineral supply chain, and AI’s role in driving some of this demand along with clean energy technologies, future growth trajectories hinge on decision-making that can factor in varying costs and benefits. More recent literature highlights AI’s potential to advance environmental justice considerations, centring community and planetary needs within larger extraction strategies. For example, authors suggest Geospatial AI modelling to identify prospective regions with lower ecological risks, and ML models to help create conservation strategies that minimise environmental degradation by integrating geological and ecological data.

A review of current and upcoming AI use cases in the mining industry frames mining as an endlessly complex array of trade-offs (e.g. between meeting budgetary constraints and reducing environmental harm). It proposes a multi-objective optimisation model framework that could balance competing objectives, such as profit, safety, land use and environmental impact, in a way that is transparent and accountable — so as to not amplify existing inequities, environmental degradation, and other harms endemic to the historic ‘resource curse’ dynamic experienced by Global South countries.

Spotlight: Critical minerals can be recycled

In its 2024 report, the International Energy Agency (IEA) stated that recycling is indispensable to the security and sustainability of critical minerals supply for clean energy transitions. Metal and material recovery from electronic waste (e-waste) creates a valuable secondary supply source, reducing reliance on new mines and providing supply security to importing countries.

In countries like India, innovators are tapping into the big business of waste, using machine learning to scale up the effective identification and sorting of e-waste in landfills while also protecting waste workers from the risk of contamination.

However, e-waste management in Asia is still a nascent economy. Rapid technological advancement renders equipment obsolete, generating unprecedented amounts of e-waste. According to a recent report, global e-waste is rising 5 times faster than documented e-waste recycling. Researchers stress the importance of a circular economy for sustainable management of e-waste, highlighting that in the absence of formal state policy, untreated dumping of waste and unscientific methods used for the recovery of metals can lead to contamination of air, soil, and water, creating toxic environments and public health hazards.

Data centres are also potential sites for reuse and recycling of obsolete equipment. A novel study proposes a computational power-driven material flow analysis framework to quantify the inflow, in-use stock, and end-of-service volume of AI servers in data centres. The researchers found that two actions in particular can reduce e-waste: 1) Extending the lifespan of AI servers by one year (keeping them in use longer) before replacement; and 2) Module reuse, which refers to the dismantling, renovation and reassembling of old key parts like GPUs, CPUs, and batteries for reuse in lower-performance computers. They note that coordinated efforts are needed across the AI value chain - model creation, chip production, data centre operation and waste disposal - to reduce waste footprint.

Around the Web

In numbers: Critical mineral production, ownership, and social unrest is an interactive map that looks at four core critical minerals - lithium, copper, cobalt, and nickel.

Researchers are constantly exploring sustainable materials for technology. In fact, Japan just sent the world’s first wooden satellite to space.

The film Demon Minerals documents the Navajo Nation’s struggle for vital living space amongst abandoned uranium mines.

The invisible seafaring industry that keeps the internet afloat is a good reminder that repair and maintenance cannot be an afterthought in this digital era.

Tuning in…

In the latest episode of Code Green, Tamara Kneese and Tom Özden-Schilling break down the complex landscape of mineral supply chains fueling global digital transformations and green energy transitions. Listen to an exploration of global extractivism, examining the environmental costs and labour implications associated with the infrastructures that underlie AI.

Credits

Research and curation: Dona Mathew, Meredith Stinger, Tammanna Aurora | Art Direction: Tammanna Aurora | Illustrations: Nayantara Surendranath | Layout Design: Shivranjana Rathore